- الديكور الخارجي والمناظر الطبيعية

-

تشييد المباني

- مقاولو الخرسانة

- هدم المباني

- منتجات البلوك والخرسانة

- مهندسي الانشاءات

- مقاولو الطرق

- البيوت الجاهزة

- سحب الحديد والفولاذ

- السقالات

- اختبار التربة

- المولدات الكهربائية

- بيع وتأجير واستيراد ونقل المعدات الثقيلة

- ترحيل المخلفات

- تسرّب المياه

- كبار المقاوليين

- الأبنية مسبقة الصنع

- الحاويات

- الحفريّات

- قواعد الأساس

- تصنيع الحديد والفولاذ

- نظام الصرف الصحي

- بناء المطارات

- صيانة المنازل

- تقديم المشورة

- الأنظمة السمعية والبصرية وتكنولوجيا المعلومات

- الأرضيات والجدران

- خدمات أخرى

- الأثاث

-

أبناء والترميم

- الحجر والرخام

- منتجات خشبية

- منتجات الجبس

- موردو مواد البناء

- الدهان

- المصاعد والسلالم الكهربائية

- الحمامات والمطابخ

- المقاول الأنسب

- مقاولون اختصاصيون

- الزجاج

- إكسسوارات المطابخ والحمامات

- أنظمة ومنتجات الجدران

- مقاولو كهرباء

- ميكانيكيون

- أعمال جبس

- موردو نوافذ

- مقاولون تسليم مفتاح

- موردو الأبواب

- الحديد والأدوات المعدنية

- مقاولون لمكافحة الحريق

- صيانة المباني

- تصاريح وتراخيص السلطة

- الموبيليا والنجارة

- أنظمة الأسقف

- المنيوم

- الإنارة

- الدرابزين

- موردي ومقاولي المعادن

- الايدي العاملة

- أنظمة الطاقة الشمسية المنزلية

- التصميم والديكور

- تنظيم المناسبات والمعارض

- التصنيفات

- حول

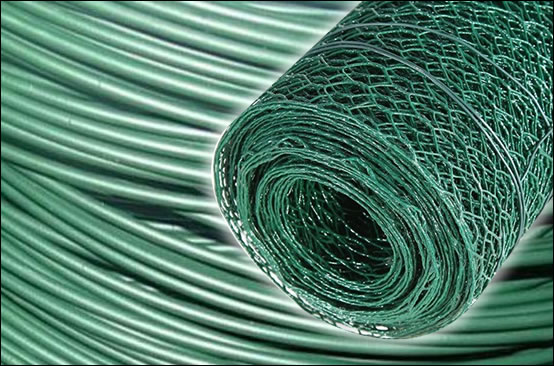

PVC Coated Wire & Wire Mesh: Solutions from Changhong, Your Trusted Manufacturer

Established in 1998, Changhong PVC Coated Wire Products Co. has been manufacturing and exporting high-quality PVC coated wire and wire mesh products for over two decades. Our dedication to quality and innovation has positioned us as a reliable supplier in the industry, providing durable and versatile solutions to customers worldwide.

Plastic Powder Coated Steel Wire

Galvanized and plastic coated wire is used in manufacturing of binding wire, tie wire, plant support wire, meshes and fences.

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics.

Color Coating Materials: PVC / PE / Vinyl

PVC is the most popular powder for coating wires, as it is relatively low in cost, resilient, fire retardant and possesses good insulating properties. The PVC coating and the inside wire are firmly bonded together to offer a longer service life. High-density hard PVC (vinyl chloride) coating is applied against the corrosion of common acids and alkalis. The service life is up to 12 years, that is several times that of hot and cold galvanized iron wire. The colors can be customized according to customers needs.

The coating materials of PVC, PE, polyvinyl chloride, can be added with anti-UV, anti-aging additives to achieve enhanced properties.

Differences of PVC coating and PVC dipping

Plastic coating is a technical processing referring to the surface processing of the metal wire. The solid plastic is melt into liquid plastic under high temperature, then the metal wire material is put into plastic flow, it is taken out after certain time. Plastic Dipping is a process referring to the surface treatment on the finished steel wire mesh. Welded or woven wire mesh is treated with PVC dipping to achieve further protection from the weather and better anti-corrosion property.

In general, plastic coating mainly applies to the wire before further weaving or fabricating. The plastic dipping normally applies to the wire mesh processed with the steel wire.

Coated Wire Applications

1. Tie Wire / Binding Wire:

PVC / PE / Vinyl coated or painted wire is made in forms easy for binding and tying uses. The wire is popularly made into cut wire, cut and looped wire, or wound in coils, around sticks.

2. Hanger Wire

3. Mesh and Fencing Wire: For making of chain link fence, gabions and various meshes.

4. Vegetable and plant suppot wire

Main Parameters of Plastic Coated Wire

1, Material before coating:

Steel wire;

galvanized wire;

redrawing wire;

annealed wire;

stainless steel wire.

The wire gauge number, tensile strength, elongation, the amount of zinc and other parameters shall be pre-determined before the plastic coating processing. Average tensile strength for the PVC coated wire ranges from 350N/MM2-900N/MM2, elongation ranges from 8% -15%.

2, Coating Color:

Common colors are grass green (light green), dark green (dark green),Gray, White.

3, General Wire diameter with and without plastic coating:

Wire diameter before coating: 0.6mm-4.0mm (wire gauge BWG23-8)

Wire diameter with coating: 0.9mm-5.0mm (BWG20-7)

Plastic layer (0.4mm-1.5mm), wire diameter deviation (+0.05 mm/-0.05mm Max)

Main Products Delivered

20 SWG PVC Coated Binding Wire

PVC Coated M.S. binding wire

Gauge: 20 SWG

Galvanized PVC Coated Wire

Green

Wire size: 14 gauge or 1.628 MM

Material: Mild drawn or rolled

Inside: 1.60mm electro galvanized wire, outer diameter:2.60mm

Tensile strength: Min. 380MPa.

Elongation: Min. 9%

Green PVC Wire to Poland

Pvc wire, green rd 2,40/2,75 mm

Pvc wire green, rd 2,75/3,15 mm

Pvc wire green, rd 1,80/2,20 mm

Rm: 450/550 NM

Colour: ral 6009 (or similar)

In coils: 400/800kg.

Supply in FCL

PVC Coated Electro Galvanised Wire 2.00mm

Specs: 1.6mm/2.0mm

Tensile Strength: 35-50kgs/mm2

Colour: Dark Green RAL6005

Roll Weight: 500kgs/roll

Packing: Inner Plastic Film and Outer Woven Bag

PVC Coated Electro Galvanised Wire 2.80mm

Specs: 2.0mm/2.8mm

Tensile Strength: 35-50kgs/mm2

Colour: Dark Green RAL6005

Roll Weight: 500kgs/roll

Packing: Inner Plastic Film and Outer Woven Bag

Galvanised wire with PVC coated, Delivered to Portuguese

Hot-dipped galvanized wire with PVC coating

Wire Diameter:

Inner 1.9mm, outside diameter 3mm

Inner 2.6mm, outside diameter 4mm

Material: Low carbon to DIN 1548

Tensile Strength (T/S) 40-44kgs/mm2 max 45kgs/mm2

Diam. tolerance to DIN 177

Zinc coating 70-80gms

PVC color RAL 6005 (dark green)

Packing: should be in coils of about 600Kgs

Annealed Wire, Plastic Coated

Pvc coated wire coils, green, inner soft annealed wire, wire diameter 3 mm after coating, delivered to Mexico market

Green PVC Coated Wire for Gabions Production

3.20 PVC Coated Wire:

Inner Wire: 2.20mm

Finish: Zn90%, Al%10 Coated ( min 230 gr/m2) +Further PVC Coated

Tensile Strength: 350 - 500 N/mm2

3.70 PVC Coated Wire

Inner Wire: 2.70mm

Finish: Zn90%,Al%10 Coated ( min 245 gr/m2) +Further PVC Coating

Tensile Strength: 350 - 500 N/mm2

3.70 PVC Coated Wire

Inner Wire: 2.70mm Zn95%, Al%5 Coated ( min 245 gr/m2) + Further PVC Coating

Tensile Strength: 350 - 500 N/mm2

PVC Coated Wire for Packing Purpose

pvc coated binding wire

Core wire diameter: 0.8 MM

Coated wire diameter: 1.2 MM

Core wire material: Galvanised wire

For packing of big bulks

Powder coated GI wire for packing, size 1.2mm

PVC Coated Galvanized Wire in Big Coils

Diameter 3.76/4.16mm

Tensile strength 45 to 50 kg/m2

Base wire zinc coating: 70g/m2

PVC Color - RAL 6005

Specifications BS EN10244 Class C.

Packing in 500KG coil

Colour Coated Steel Wire, in Black and other Colors

19 gauge tie wire, with black PE coating, white, blue and other colors available

- مقاولو الخرسانة

- هدم المباني

- منتجات البلوك والخرسانة

- مهندسي الانشاءات

- مقاولو الطرق

- البيوت الجاهزة

- سحب الحديد والفولاذ

- السقالات

- اختبار التربة

- المولدات الكهربائية

- بيع وتأجير واستيراد ونقل المعدات الثقيلة

- ترحيل المخلفات

- تسرّب المياه

- كبار المقاوليين

- الأبنية مسبقة الصنع

- الحاويات

- الحفريّات

- قواعد الأساس

- تصنيع الحديد والفولاذ

- نظام الصرف الصحي

- بناء المطارات